Q1-what sensors are your system using and what sensors would i need to use hard bearings? Do you offer sensors to work with hard bearings?

A1 yes, we offer sensors for hard bearing. it's sensors of the force (pressure). See pictures below.

Installing sensors and balancing stand supports construction

Installing sensors

Sensors

Q2 How much movement in the bearings is needed to measure unbalance?

A2 "movement in the bearings" - is it RPM or deformation of the supports?

Lowest RPM is 400-600 RPM.

Q3 Do i need 4 planes to ballance crankshafts and flywheels? Does the plane refer to positions along the shaft being ballanced or does it refer to the axis of measurement?

A3 No, to balancing crankshafts 2 planes balancer required, (4-planes no needed), because it's a rigid .

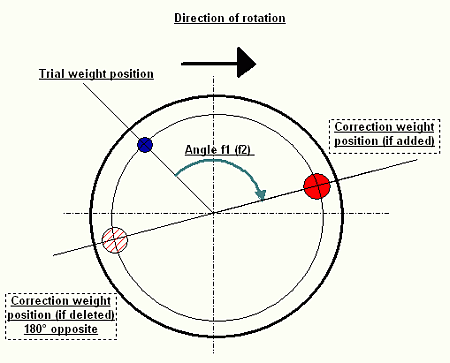

About balancing planes see picture below

Q4 -do i need a degree wheel to find the point of correction after ballancing or will the software and laser locate the position as i turn the crank by hand or is this only possible using a encoder sensor for rotational measurement? Is it possible to get this system with encoder instead of laser tach?

A4 Laser is used as zero point sensor only. It can't show point (position) to add correction weight. Software show correction weight position (angle) from testweight position. You can use degree wheel to counting angle or encoder to counting angle by software. Using laser and degree wheel is more simple.

Q5-do you have more pictures, drawings or measurements of the sensors? Are the sensors directional when you fit them to the bearings?

A5 Yes, see above

Q6--What is the software requirements? Can i for instance use a windows based tablet?

A6 You can use any Windows from XP to Win10, but not WinCE.