Dear Alexandar

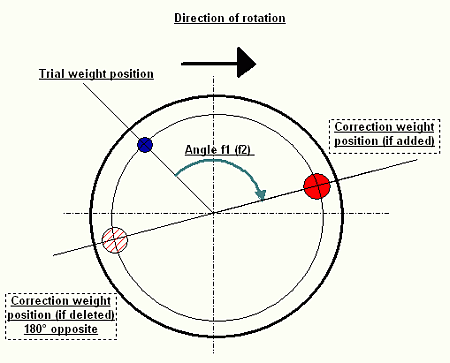

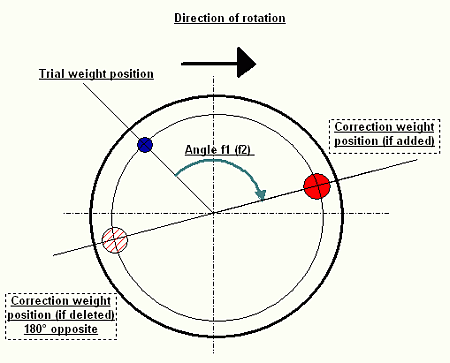

1. Be sure that you put the weights in the correct place (angle)

The angle is measured from trial weight position according direction of rotation (as shown on picture below)

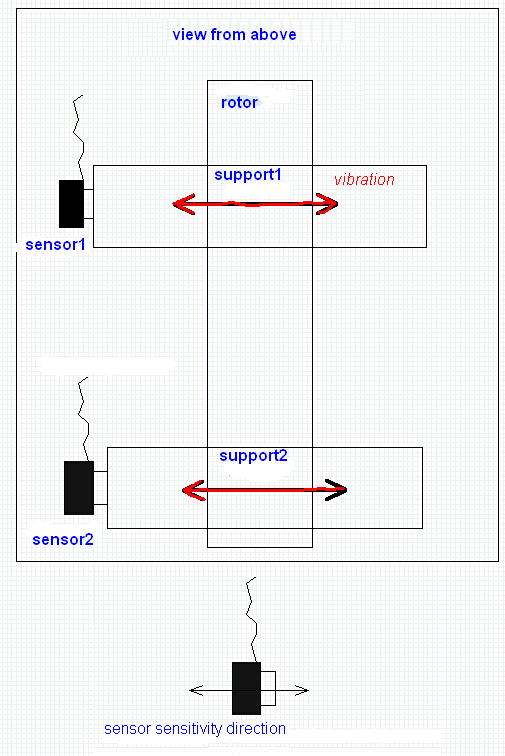

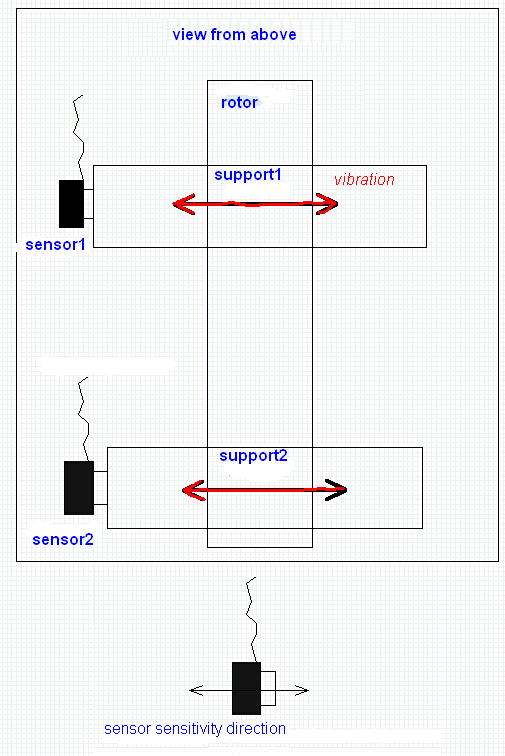

2. Be sure that you correctly mount vibration sensors.

I.e. sensor sensitivity direction should be transversely (at right angle) to rotor axis.

3. If you have an balance machine with "soft bearing" you can try use balanset with this machine for testing.

Balanset should to show the same weights as another software, maybe to other angle - according to direction of rotation of rotor.

Or you can for beginning try balanset to balance a simple rotors - maybe a small fan etc.

There are video

https://www.youtube.com/watch?v=dzUkNHeFcVM Also there are Step-by-step balancing procedure manual

https://vibrobalance.com/index.html Best wishes

Andrew Shelkovenko